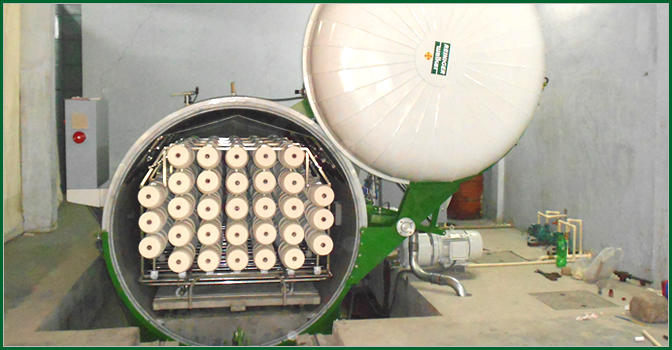

YARN CONDITIONING PLANTS (YCP)

The purpose of YCP-Conditioning of yarn is to restore the natural properties of strength and elongation by thermo dynamic principle. The system should follow the basic physics of “Steam can be generated at low temperature if the pressure is low” – in other words, the pressure and temperature are directly proportional.

REINIGER WELKER YCP follows the thermo dynamic principle for gentle treatment of yarn by producing cold saturated steam in a separate energy source and avoids contamination of yarn in the conditioning chamber.

Model: ABR 500 (500 Kgs / Batch), ABR 750 (750 Kgs / Batch), ABR 1000 (1000 Kgs / Batch) and ABR 1500 (1500 Kgs / Batch).

ADVANTAGES OF YCP:

- Increase in single yarn elongation and strength

- Significant reduction in fly liberation

- Free from electrostatic charges and better hairiness value

- Increased efficiency of knitting machines due to less unwinding tension and fewer needle breaks

- Good size pickup in sizing

- Better performance in good cloth formation and fabric softness

Cotton, Cotton Mercerized, Wool, Silk, Polyester, Viscose-Rayon, Blends like PV/PC in Cop, Cone and hank from can be treated for conditioning and heat setting with homogeneity – TWO IN ONE MACHINE.

Conditioning from 46°C to 120°C

TECHNICAL SPECIFICATION

| Description | ABR – 500 | ABR – 750 | ABR – 1000 | ABR - 1500 |

| Capacity / batch | 500 kgs | 750 kgs | 1000 kgs | 1500 kgs |

| Production | 12 Tons | 18 Tons | 24 Tons | 36 Tons |

| Vessel Diameter | 2000 mm | 2000 mm | 2000 mm | 2000 mm |

| Feeding of Cones | Manual / Auto | Automatic | Automatic | Automatic |

| Energy source | Separate EV Heater / Steam | Separate EV Heater / Steam | Separate EV Heater / Steam | Separate EV Heater / Steam |

| Water Req. | 15L for Steam gen. | 22L for Steam gen. |

28L for Steam gen. | 45L for Steam gen. |

| Operating Temperature | Up to 120”C | Up to 120”C | Up to 120”C | Up to 120”C |

| Operating Pressure | -33 to 1013 mbar | -33 to 1013 mbar | -33 to 1013 mbar | -33 to 1013 mbar |

| Req. Load | 84.5kW | 84.5kW | 121 Kw | 157Kw |

| Power Consumption | 16 – 18 kWhr | 17 – 19 kWhr | 22 – 24kWhr | 28 – 30 kWhr |

| Req. Area | 7x4Mtr | 8.5 x 4 Mtr | 10 x 4 Mtrs | 13.5 x 4 Mtrs |