BOBBIN TRANSPORT SYSTEM (BTS)

The purpose of BTS – Bobbin Transport System is to transfer the bobbins from Speed frame to Ring frame without stain or sweating mark, protecting the surface of roving wound on bobbins, eliminating the intermediate storage area for bobbins, protecting the components of auto-doffing arrangements and other machine parts in a proper way of handling the material to achieve “HUMAN TOUCH FREE YARN”.

Model: Manual, Semi-automatic and fully automatic.

Manual

Speed frame and Ring Frame will be connected with overhead track-way by means of necessary pillars, brackets, bends, change over switches and bobbin trains. Bobbins will be loaded in to the trains and the movement of Bobbins/ Trains will be done manually by pulling the hand wheel of bobbin trains.

Doffing at speed frame ----> Loading of Bobbins in Train ---------> Manually pulling the train to the Ring Frame ----> Loading of empty Bobbins ----------> Bring back the train to speed frame.

Semi–Automatic:

Speed frame & ring frame will be connected with overhead track- way by means of necessary pillars, brackets, bends, change over switches and bobbin trains. Bobbins will be loaded in to the trains and the movement of Bobbins / Trains will be done by geared motor up to the Buffer stock area. The movement of Bobbins will be done manually from Buffer Stock to Ring frame and empty Bobbins from Ring frame to Buffer stock.

Doffing at speed frame ----> Loading of Bobbins in Train ---------> Movement of trains by geared Motors to Buffer stock area ----> Movement of Bobbins from Buffer stock to Ring Frame manually ----> Loading of empty bobbins and bringing back the train to Buffer stock manually ---------> Movement of empty bobbins from Buffer stock to Speed frame by geared motors.

Fully Automatic:

Speed frame and ring frame will be connected with over head Track-way by means of necessary Pillars, bracket, bends, change over switches and bobbin trains with fixed link block creel arrangements / closed circuit arrangements. Bobbins will be loaded in to the trains and the movement of Bobbins / Trains will be done by geared Motors in a closed circuit arrangement.

Doffing at speed frame -----------> loading of Bobbins in Train -----------> Movement of trains by geared Motors to Ring frame ----------> Loading of empty Bobbins manually and bringing back the trains to speed frame by geared Motors.

FEATURES

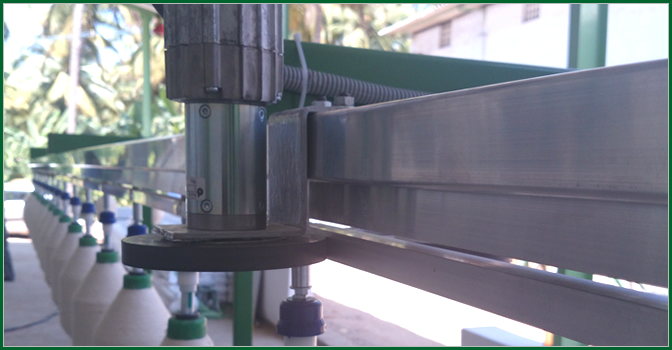

- Specially designed fully enclosed Aluminum track-way

- Smooth surface finish ensures proper movement of trains and bobbins

- Connectors, Brackets and Guide rollers are of Polymer material

- German made components for longer life

- Very easy to move bobbin trains in case of manual arrangement

- Pre-fabricated structures for easy installation

- Experience on installation of OHTC helps for compact design

OPTION: Manual – Economical (Extended track-way in Ring frames)